Touchsensor

zum Auslösen der Messung

7 Zoll Touchdisplay

Kameraaktivierung und Zoom

Vertikale Dreheinheit mit

Laserentfernungsmesser

& 5-Megapixel-Kamera

zur optischen Zielwahl und Bilddokumentation

zur Datenübertragung zwischen Messgerät und PC

In beiden Achsen 360° schwenkbar

Messen in allen Dimensionen,

ohne „toten Winkel“

Carbonfaser-Stativ

leicht zu tragen, sicher im Stand

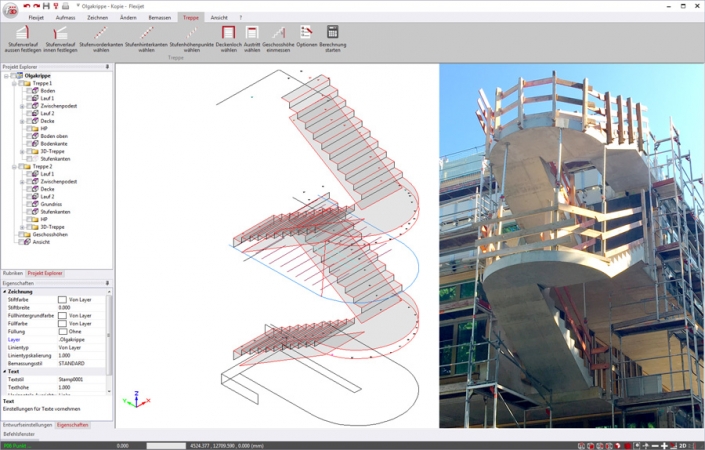

With Flexijet 3D, literally everyone can quickly, efficiently and cost-effectively take measurements and assess dimensions accurately to the millimeter precise, and insert the data directly into CAD. Whether you are a beginner, an all-rounder or a CAD specialist, with Flexijet 3D you benefit from the principle of “measurement drawing”, which offers you a multitude of advantages over conventional measuring techniques and point clouds from laser scanners.

Inaccurate measurements or transposed digits are a thing of the past. You do not need to make notes of measurements because you can see what you’re measuring right away on the display. The possibility to include photos and audio notes in the measurement drawing offers you integrated documentation on site. You can easily work in difficult locations without scaffolding, ladders or other helpers.

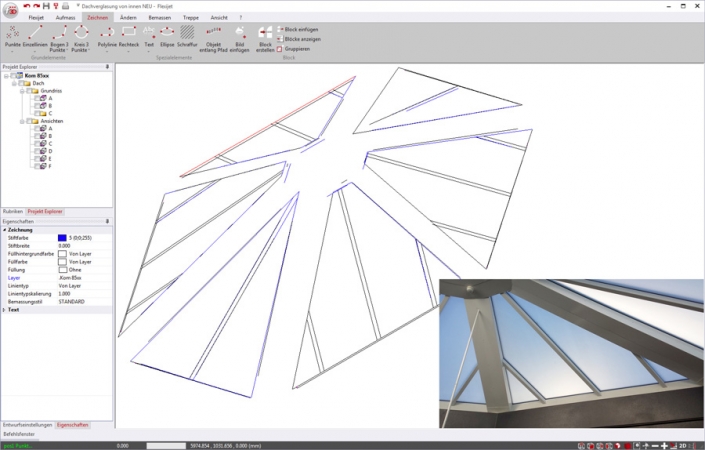

Measure furnished rooms without having to move irritating furniture. Roundings, arches and non-angular components can be detected quickly and precisely. Thanks to the projection function, you can also use Flexijet as an assembly aid. The application possibilities of the Flexijet 3D are just as versatile as the users who use this revolutionary laser measuring system.

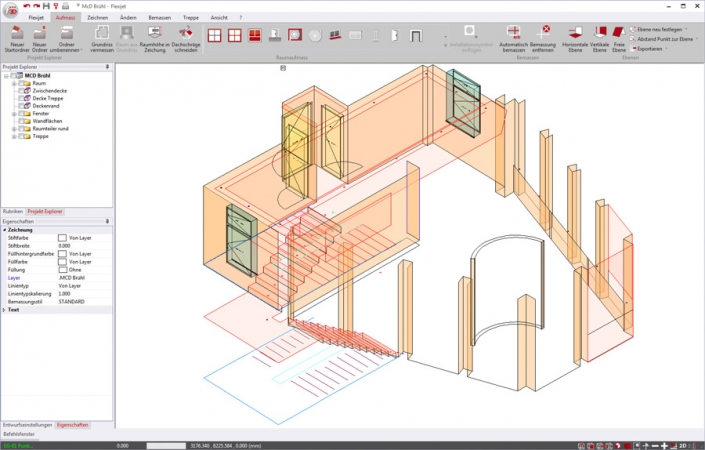

For this purpose, it is not necessary to set the measuring points in the room corners. The software automatically cuts the straight line of a wall off as it reaches the extended straight line of the adjoining wall. All angles of the walls connecting to each other are accurately detected during the swift site measurement.

For this purpose, it is not necessary to set the measuring points in the room corners. The software automatically cuts the straight line of a wall off as it reaches the extended straight line of the adjoining wall. All angles of the walls connecting to each other are accurately detected during the swift site measurement.

Flexijet 4ARCHICAD offers an interface to Flexijet 3D especially for Graphisoft Archicad users. Here, the Flexijet 3D measurement hardware is integrated directly into Archicad. This allows users to “measure-model” with the Flexijet measuring device in their familiar working environment, directly in Archicad.

Flexijet 4ARCHICAD offers an interface to Flexijet 3D especially for Graphisoft Archicad users. Here, the Flexijet 3D measurement hardware is integrated directly into Archicad. This allows users to “measure-model” with the Flexijet measuring device in their familiar working environment, directly in Archicad.